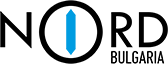

ISO 9001:2008

NORD has implemented the ISO 9001:2008 quality management system which has been approved by IQNet for the development, manufacturing, repair and sale of agricultural and industrial equipment, spare parts and castings.

IQNet 9001:2008

IQ Net is an international certifying organization established in 1990 in Bern, Switzerland. It has more than 40 certification partners and more than 200 subsidiary companies world-wide.

ISO 14001:2004

The company successfully implement, maintain and strive to improve the system for environmental management, in accordane with the requirements of ISO 14001:2004

IQNet 14001:2004

IQ Net is an international certifying organization established in 1990 in Bern, Switzerland. It has more than 40 certification partners and more than 200 subsidiary companies world-wide.

BS OHSAS 18001:2007

NORD AD presents its current and potential customers the new system for managing health and safety at work, in accordance with the standard BS OHSAS 18001: 2007

IQNet BS OHSAS 18001:2007

IQ Net is an international certifying organization established in 1990 in Bern, Switzerland. It has more than 40 certification partners and more than 200 subsidiary companies world-wide.

Bulgarian Register of Shipping

The company has been certified by the Bulgarian Register of Shipping to manufacture and repair hull constructions and castings; to process mechanically workpieces, elements and substructures of ship machinery and mechanisms.

State Agency for Metrological and Technical Surveillance

NORD has a certificate from the State Agency of Metrological and Technical Surveillance to carry out maintenance, major repairs and reconstruction of containers under pressure, piping for steam and hot water, hoisting equipment, freight cabeways, elements and substructures of industrial gas equipment etc.

Welding certificate

Certificate of all technological processes available for the implementation and control of welding activities.

Certificate of conformity of the factory production control

This certificate certifies that all requirements regarding the assessment and verification of constancy of performance as described in Annex ZA of system 2+ EN 1090-1:2009+A1:2011 have been applied and that production control in the establishment has been evaluated in compliance with applicable requirements.

The company maintains a lab for chemical analysis, mechanical testing of metals and cast materials as well as non-destrucive testing with the purpose of providing and controlling the quality of the final output.

- SPECTROLAB 15 – 4 programs

- Dye-penetrant inspection

- Elcometer – a device to measure the dry film thickness of the applied anti-corrosion coatings

- Contactless temperature measurement

- Equipment for hardness testing:

- portable hardness meter – allows to control the hardness of workpieces specified by the customer – HL, HV, HB, HRC, HRB, HS scales

- stationary hardness meter – HRS, HRB scales

- Pump testing stand – up to 10 atmospheres pressure

The mechanical workshop is a separate structural unit which is divided into:

Premachining Section

In this section sheet and rod material is prepared for the subsequent mechanical processing. We have:

- A CNC-controlled plasma cutting machine combiHydraulic press brake CNC with length ned with a gas burner for the cutting out of workpieces with thickness up to 300 mm

- A bandsaw

Bending Section

The bending section is equipped with the following machines:

- A hydraulic press brake with maximum bending power up to 320 t, length 3,100 mm and CNC control.

- A four-roll hydraulic machine with CNC control, to bend sheet material with length 2,550 mm, for width of 25 mm and minimal diameter up to 385 mm

Mechanical Processing Section

- A Skoda horizontal-boring machine for the machining of hull workpieces with dimensions up to 8,000 x 4,000 x 2,000 mm and weight up to 25 t.

- A vertical turning and boring machine for the machining of rotational workpieces with diameter up to 4000 mm and height up to 2,000 mm.

- A wheel lathe for the processing of rotational workpieces up to 2,000 mm, with length of 3,200 and weight up to 16 t

- A center-type grinder for workpieces with diameter up to 360 mm and length 2,000 mm, and a surface grinder for workpieces with dimensions 2,000 x 500 x 400

- A gear hobber for the machining of gear wheels up to m=16 and diameter 2,000 mm

- Universal lathes for the machining of workpieces with diameter up to 1,000 mm and length up to 8,000 mm

- A planing machine for workpieces with dimensions up to 3,000 х 1,000 х 900 mm

- Shaping machines for the machining of workpieces with dimensions up to 1,300 mm and height 400 mm;

Millwrights, Machinists and Hull Fitters Section

The section is equipped with manual tools, stationary drilling machines, a site for the manufacture of metal structures.

Welding Section

We have at our disposal equipment and qualified staff for electric arc welding with coated electrodes, – Process 111, and welding with consumable electrode wire and active shielding gas - Process 135

Anti-Corrosion Coatings Section

The joint-stock company NORD AD provides guarantees for all manufacturing goods by offering the application of anti-corrosion coatings following the customer's specified parameters.

On its territory NORD AD has set up a blasting chamber with dimensions 10,000 х 6,000 х 4,000 mm and a chamber for airless painting witth dimensions 10,000 х 6,000 х 4,000 mm.

AplasmacuttingmachinewithCNCcontrolforcuttingoutofmetalsheetswithmaximalthicknessofboring up to 32 mm and 50 mm from the edge of the sheet. The machine is combined with a gas burner for cutting out of workpieces with thickness up to 300 mm. The plasma cutter comes with True Hole® technology for exact cutting and precision up to 0.1 mm.

A four-roll hydraulic machine with CNC control for bending sheet material with length 2,550 mm with height up to 25 mm and minimal diameter up to 385 mm.

The NORD AD foundry shop has many years of experience in the production of castings of ferrous metals destined for: the chemical and cement industry, machine building, power production, shipbuilding and ship repair.

Equipment

- Electric arc furnace with capacity of 1500 kg – 1 piece

- Induction furnace with capacity of 450 kg – 2 pieces

- Shot-blasting machine with capacity of 1000 kg – 1 piece

- Sand muller with productivity of 4 t / hour

Heat-treatment furnaces with the possibility of thermal treatment up to 1100°C:

- Box-type heat-treatment furnace with movable hearth and a device recording the operation mode – workspace dimensions 3,000 mm х 2,000 mm х 1,500 mm – 1 piece

- Heat-treatment furnace with workspace dimensions 1,450 mm х 700 mm х 500 mm

- Heat-treatment furnace with workspace dimensions 800 mm х 430 mm х 400 mm

- Heat-treatment furnace with workspace dimensions 420 mm х 240 mm х 170 mm

Castings are made of:

- plain carbon (unalloyed) steel

- ow-alloyed steel

- wear-resistant cast-iron

- flake graphite cast iron

- corrosion-proof stainless steel

- other types chosen by the customer

The casting capacity for iron-based alloys comprises 50 tonnes per month.

Model Equipment

Starting from 1997 NORD AD has been stocking on a large variety of model equipment needed to satisfy the requirements of our customers. If necessary, NORD also creates such equipment.

Chemical Industry

The joint-stock company NORD AD continues the traditions of the RMZ-Devnya mechanical repair plant for the repair, maintenance and assistance during the construction of chemical plants such as Agropolychim - for the production of fertilizers.

Certificates: ISO 9001:2008 BRS SAMTS

Clients

Cement Industry

NORD AD has many years of experience in the manufacturing of spare parts and units as well as the repair of equipment owing to its cooperation with the Devnya Cement Plant and other cement plants in the country. The key priorities of the company in this field are as follows:

Certificates: ISO 9001:2008 BRS

Clients

Shipbuilding Industry

The company is certified by the Bulgarian Register of Shipping to carry out the following activities: Manufacturing and repair of hull structures and castings; Repair of mechanisms, systems and appliances; Machining of workpieces, elements and substructures of ship machinery and mechanisms

Certificates: ISO 9001:2008 BRS SAMTS

Clients

Extractive Industry

NORD AD works in the field of mining and inert substances, offering to its customers innovative constructive solutions and more stable materials. The scope of activities offered by by the company offers, includes:

Certificates: ISO 9001:2008 BRS

Clients

Power Production

The highly-qualified staff and experts, the excellent technical equipment and experience allow NORD AD to be preferred by its customers in this distinctive industry. Everybody at NORD AD is aware of their high level of responsibility when manufacturing and repairing goods in the field of power production.

Clients